Our vibrating spiral elevator is made up of several designs that utilize different methods to achieve high efficiency upwards conveyance.

Our vibrating sieves and screen equipment are specially designed to sift through pelletized materials used in plastic production to ensure impurities and defective materials are removed from the production process in real-time.

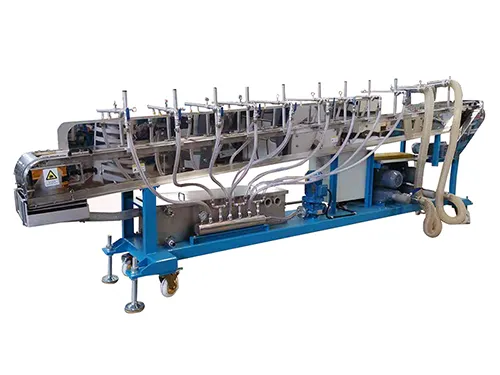

The gantry pellet pelletizer is suitable for cutting materials after the extrusion and thermoplastic drawing of thermoplastic elastomers, high filling materials and glass fiber composite materials. The pelletizer is capable of cutting material into different sizes.

Read MoreThe high efficiency bulk material mixer is suitable for the mixing various fine powders and granular materials in plastics, chemical raw materials and refractories.

Read MoreThe block resistant, reflux resistant cleaning station works in conjunction with plastic extrusion equipment to cool and purify materials using a devolatilization gas to prevent extruder material overflow in the vacuum system. Blocking prevention is caused by the oil condensate, and the vacuum pump impeller scale's performance.

Read MoreDesigned to efficiently eliminate resin residue from mixing screws by cutting-edge vacuum carbonization technology, our vacuum screw cleaning machine cleaning method greatly increases the lifetime of your screws by guaranteeing a complete, residue-free, damage-free cleaning process and thereby lowers manufacturing expenses. (ZL 2020202157 Patent No.)

Read MoreTo better serve our customers, using European modified engineering plastic factory standard processes, we can upgrade their original plastic production lines, or redesign them in order to achieve a higher production efficiency, with less equipment space and a lower energy consumption.

Read MoreWe provide you with one stop solutions answering your needs for efficient plastic processing and increased production capacity.

Plastiger machinery focuses on the design and production of engineering plastics auxiliary machines, such as lifting equipment, drying equipment, dehydration equipment, screening equipment, mixing equipment, feeding equipment, mixing equipment, and granulating equipment. Additionally, we provide outstanding upgrading and transformation services for the existing engineering plastics production lines of our customers.

Our advantage is not only a supply of equipment, but also the design of comprehensive plastic production plans based on your factory, production line, and production requirements to help you improve the competitiveness of your enterprise.