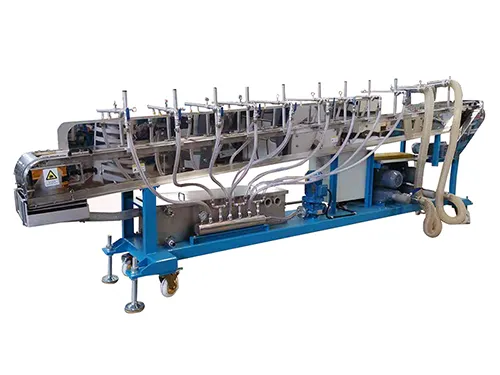

Features

- The moisture content of a typical nylon product treated with this equipment can be stabilized below 0.08% due to its superior suction. The dehydration efficiency is higher than that of a traditional air blower, and the surface water removal rate is above 99%.

- The air knife dewatering unit is suitable for high glass fiber reinforced products with a wear-resistant ceramic suction head. It not only has a small resistance to passing through the material, but is also easy to clean.

- The air knife dewatering unit can be used for the dewatering of LFP long glass fiber reinforced material due to the guide slot that is designed to prevent material blocking.

- The air knife dewatering unit uses backwash flow to prevent the drain from being blocked for long periods of time.

- It achieves a high - efficiency separation of gas and liquid using the multiple-cyclone separator in the case. It will not be blocked, and it is easy to clean, with the suction head wind speed reaching up to 25m/s due to the lack of a filter and the small wind resistance pressure loss.

Operational Principle

The dewater air knife uses a negative high-pressure produced by the high-pressure blower in order to quickly remove the surface water of the wet materials. The gas-liquid mixing flow separates the liquid through the high efficiency eddying flow and automatically collects it in the tank for discharge.

Tags

dewatering equipment, dryer, pellet drying