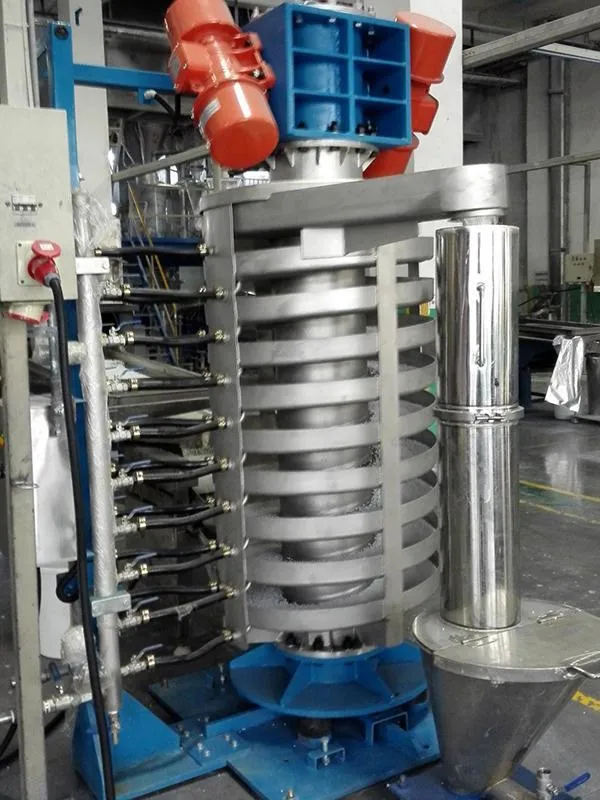

Electric Heating Spiral Conveying Dryer

Applications

The electric heating spiral conveying dryer uses a high heat-conducting oil to heat the materials, and the rated drying capacity is 500-4000kg/h. The maximum surface temperature of the vibration disk can reach more than 200 degrees. It is suitable for materials with ultra-high temperature heating and drying requirements. It has obvious value added effects in the use of modified engineering plastic production line.

Material types

Vibrating spiral conveyors are standard equipment for many industries to elevate bulk materials. They can convey, dry and cool the plastics granules, rubber granules, chemical and pharmaceutical intermediates, metal salts, welding powder, glass batch, catalysts, abrasives and ash as well as milk powder, powdered coffee, tea, nuts, nutrients and cereals.

Strand Pelletizing Line

Strand Pelletizing Line

Underwater Pelletizing Line

Underwater Pelletizing Line

Air-cooled die-face pelletizing

Air-cooled die-face pelletizing